WindESCo Closes $10M Series B Financing

BURLINGTON, MA – April 29, 2020 – WindESCo, Inc., a wind energy performance optimization company today announced that it has closed a $10 million...

1 min read

Sample HubSpot User

Mar 26, 2019 10:02:00 AM

Sample HubSpot User

Mar 26, 2019 10:02:00 AM

BOSTON, MA - February 11, 2019

BOSTON, MA - February 11, 2019

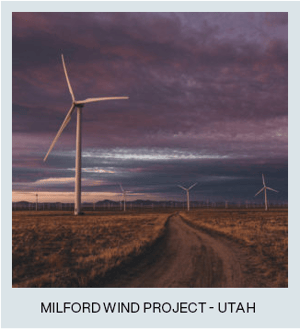

WindESCo provides services to windfarms to improve energy production and reduce operating expense. To further advance wind farm operations, WindESCo is integrating the results of recent research conducted by the U.S. Department of Energy ‘s (DOE) National Renewable Energy Laboratory (NREL) into WeBoost Advanced, a solution that unlocks additional value by enabling live communication between turbines in an operating wind farm. In such wind farms, whacall “soct we ial windfarms”, turbines learn from and help each other to increase plant output and reduce operating costs.

A large-scale case study to evaluate the potential for collective yaw optimization, an aspect of “social windfarms”, on a 145 MW windfarm was conducted through a joint project between WindESCo and NREL, funded by a DOE Small Business Voucher Program grant. The Services division of Longroad Energy provided valuable inputs that also contributed to the successful project.

The most common approach to windfarm control for increased energy production is wake steering – yawing an upwind turbine to direct its wake away from downstream turbines. However, not all windfarm layouts are conducive to utilizing this. Recent research at NREL has identified opportunity for energy improvement by improving the alignment of the turbines with the overall wind flow, so turbines don’t react to localized flows. This method utilizes the wind direction information from all the turbines to correctly adjust the nacelle position of each machine for maximum energy production.

In this project, real high-speed data collected from the wind farm was analyzed to demonstrate the potential benefits of implementing collective yaw control on a windfarm. Results of this work have been published and show that for the windfarm studied an annual production increase of more than 2% could be achieved by implementing the proposed windfarm control strategy. A 31% reduction in yaw drive travel and thus wear of yaw drive components was also achieved resulting in a substantial life extension to yaw drive components.

###

About WindESCo, Inc.

WindESCo provides services to windfarms to improve energy production, reduce operating expense and increase lifetime. Combining the power of physics-based models with data science, WindESCo’s solutions are actively optimizing wind farms in 8 countries on 3 continents.

Media Contact

WindESCo

Press Office

1-781-206-2225

press@windesco.com

BURLINGTON, MA – April 29, 2020 – WindESCo, Inc., a wind energy performance optimization company today announced that it has closed a $10 million...

Kyle Willoth joined the WindESCo team as Customer Operations Manager this month 🎉

Anca joined the WindESCo team as an addition to our European sales department!