Understanding why it's worth continuous monitoring at a wind farm

Historically many companies focused on one-time projects to correct issues on a farm, but at WindESCo we chose to transition to providing continuous insights into your wind farm for many key benefits.

Provides near-immediate feedback and insights to performance

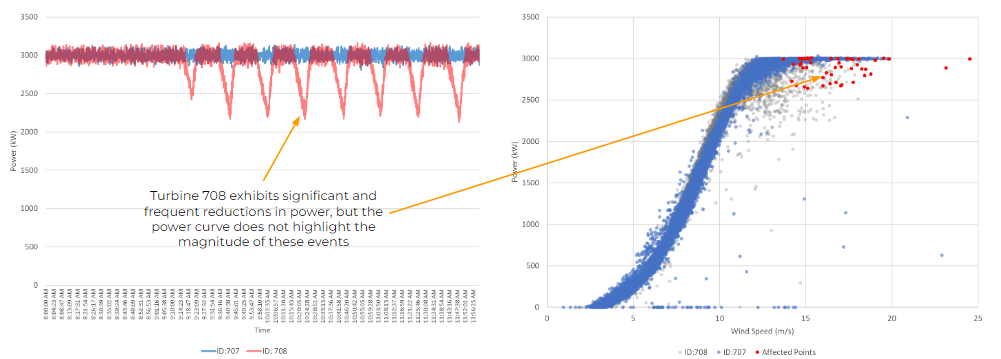

When choosing to run a one-time project, companies are often looking a 6-12 months in retrospective. While useful in identifying issues that crop up it limits that type of response that a site team can complete and those delays have real-world costs. For example, it's useful to know that turbine 708 was shutting down frequently, but addressing something after a year would have delayed this customer regaining $32,000 per annum. And when it's something as simple as a converter fan replacement, it's nice to have the peace of mind right away. WindESCo runs checks on a daily basis so you can be sure that if something new crops up that needs to be addressed, you'll be able to be on top of it right away.

Allows companies to identify trends

In this ever digitalizing world everyone talks about the importance of data - and it is useful! But data is only as valuable as the knowledge and insights that is provides.

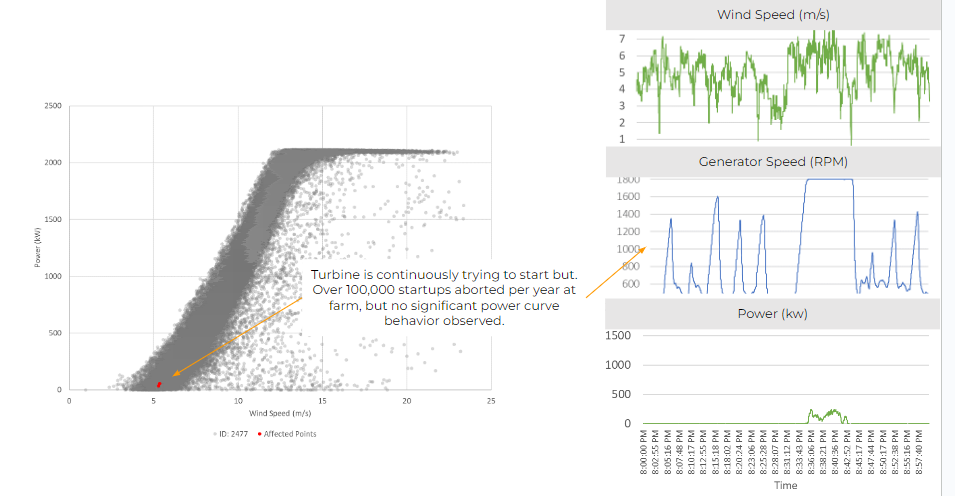

WindESCo flags actionable insights for its customers to ensure that you can jump to the final step - focusing on what should be addressed. This distillation to root causes also simplifies the ability to tease out trends and macro issues that may impact your farm. For example, when this turbine had its start-up parameters adjusted it reduced the AEP by 1%. And when the customer realized the same issue was cropping up on many other turbines, it revealed that a software update had defaulted the parameter causing a $42,000 impact.

Increased decision-making capabilities

One of the most important aspects of running a wind farm is making the right decisions based on the market conditions. Understanding when is a good time to upgrade your blades, or when it's ok to defer maintenance a few months can make or break an operating year. And when you're making business decisions, it's essential to have relevant and accurate information on hand to inform your approach.

Maintaining continuous monitoring is an important piece of the puzzle as it provides asset managers the understanding of the current operations on the plant. Using this knowledge, farms have the ability to adjust dynamically to market conditions and exploit every possible opportunity.